Turnell & Odell

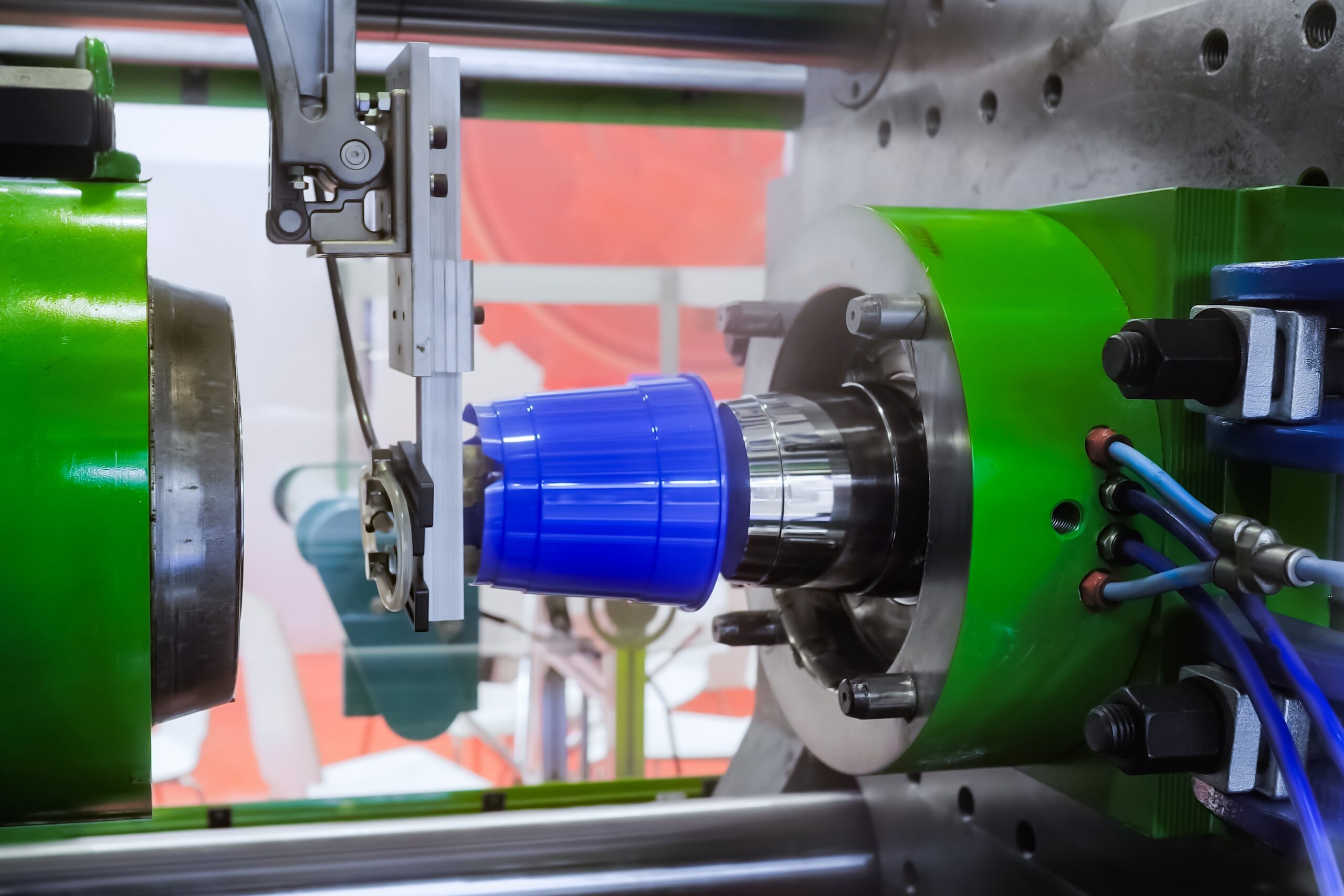

Plastic Injection Moulding

Turnell & Odell deliver high-accuracy engineering solutions to support the demanding world of plastic injection moulding. With decades of experience in CNC machining, tool-steel processing, component finishing and complex assembly, we help moulding companies achieve exceptional repeatability, durability and consistency within their moulding operations. Our focus on precision ensures every mould tool and machine component performs flawlessly under continuous production cycles.

Why Injection Moulding Depends on Precision Engineering

In plastic injection moulding, even the smallest deviation can impact part quality, cycle time and tool life. High-pressure moulding environments require components engineered to withstand heat, stress and constant operation. Turnell & Odell produce the precision-machined parts, assemblies and tool components that ensure moulds run efficiently, maintain dimensional accuracy and deliver consistent outputs across long production runs.

Precision

UKs Best

Why the Defence Industry Chooses Us

Skills

Supporting Tooling, Inserts & High-Wear Components

Injection moulding relies on hardened, high-performance tooling built to withstand extreme pressures and temperatures. Turnell & Odell manufacture core pins, ejector housings, guides, cavities, inserts, backing plates and high-wear components to precise specifications. Our meticulous machining and finishing ensure exact fit, minimal friction and improved mould longevity — reducing tooling downtime and maintenance requirements.

From Prototype Tools to Production-Ready Components

Whether you need prototype mould inserts during the development phase or full-scale production components for long-running moulds, Turnell & Odell offer scalable, dependable support. Our engineering capability allows moulding businesses to optimise design iterations, accelerate tooling readiness and enhance production efficiency. We help streamline the journey from concept to finished mould tool.

Quality, Accuracy & Reliability for Moulding Operations

Injection moulders demand absolute reliability. Turnell & Odell operate with ISO-aligned quality systems, advanced inspection equipment and strict process controls to ensure consistency across every component. Our expertise helps moulders maintain cycle consistency, reduce defects and improve part-quality repeatability — contributing directly to stronger production performance.

Partner With Turnell & Odell for Injection Moulding Engineering

By working with Turnell & Odell, you partner with a precision engineering specialist that understands the challenges of injection moulding. From high-wear inserts to complex assemblies and tooling components, our engineered solutions support reliability, improve mould performance and deliver long-term value across every production cycle.

Turnell & Odell

Contact Us Now

Address

Sanders Road

Finedon Road Ind. Estate

Wellingborough

Northants

NN8 4NL

Book By Phone

+44 (0) 1933 222061