ISO 9001:2015

Quality

Our reputation is built on delivering manufacturing you can trust, supported by strict inspection processes, documentation control and industry-recognised quality practices.

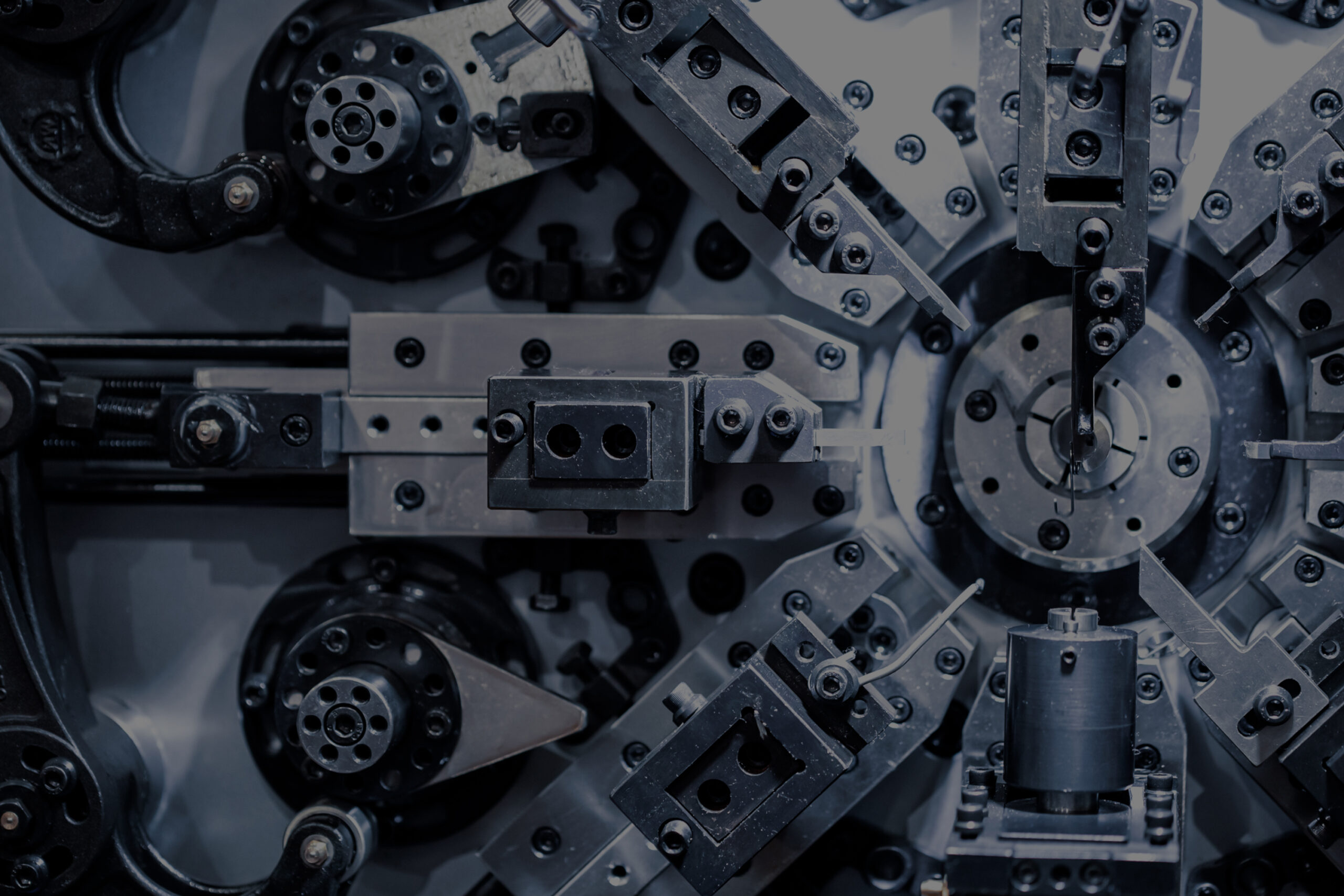

At Turnell & Odell, precision engineering is more than what we do — it’s who we are. Every component we manufacture is supported by robust, proven quality systems designed to give our customers complete confidence in performance, consistency and traceability.

Our reputation is built on delivering manufacturing you can trust, supported by strict inspection processes, documentation control and industry-recognised quality practices.

If you’re searching for CNC milling services near me, precision machining UK, or a CNC company to make your parts, Turnell & Odell deliver fast, reliable and cost-effective solutions.

Turnell & Odell

A Quality Framework You Can Rely On

Production Part Approval Process (PPAP)

For critical components and high-value applications, our PPAP ensures parts consistently meet specification before full production begins. This structured validation process gives our clients the assurance that quality, repeatability and performance are built into the manufacturing workflow from day one.

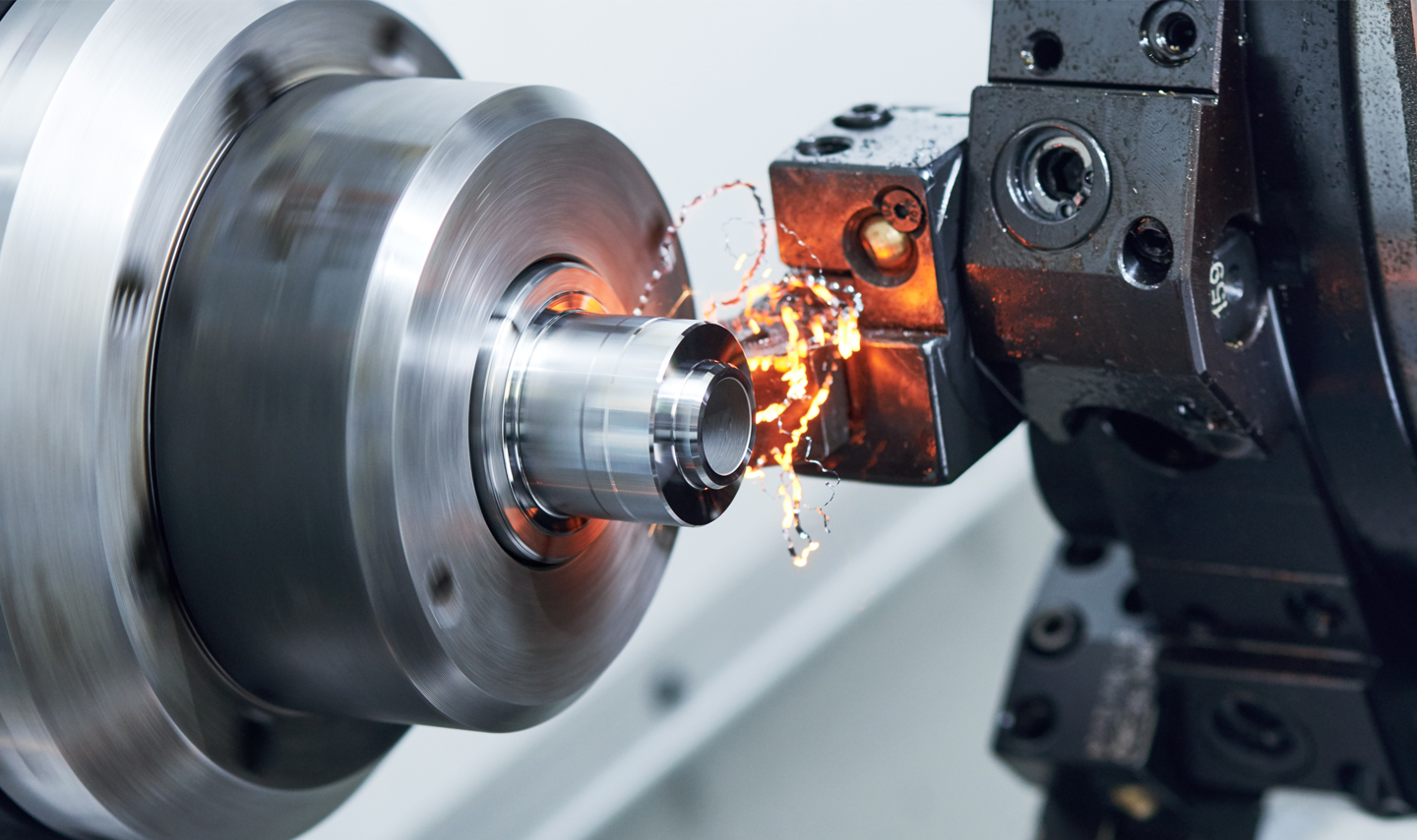

First Article Inspection Report (FAIR)

Every new project benefits from comprehensive FAIR documentation, where the first component off the line is inspected, measured and verified against all drawing and specification requirements. This ensures accuracy is established at the very start of production.

Initial Sample Inspection Report (ISIR)

Our ISIR process provides detailed inspection results for sample components, confirming dimensional accuracy and compliance before production proceeds. It’s a critical part of our commitment to getting it right the first time — and every time.

Certificate of Conformity (COFC)

All supplied components can be delivered with a COFC, guaranteeing they meet agreed specifications, industry standards and customer requirements. This documentation is essential for regulated sectors where compliance and traceability cannot be compromised.

Precision Engineering Services

Get In Touch With Us

Call us anytime

+44 (0) 1933 222061

Email us

sales@toengineering.co.uk

Get A Quote

Certificate Downloads

Total Transparency and Complete Traceability

Why It Matters

Our approach to precision engineering is built on one philosophy: quality is not optional.

By integrating robust quality controls, documentation and inspection processes into every stage of production, Turnell & Odell delivers components that meet demanding tolerances, achieve consistent repeatability and exceed customer expectations.

Full Material Traceability

From raw material to finished part, every stage is recorded and traceable. Batch numbers, mill certificates and processing histories are documented to ensure total transparency. This level of control is vital for industries such as aerospace, defence, medical and energy where material integrity is critical.

In-Process Inspection Reporting

Quality isn’t just checked at the end — it’s monitored throughout. Our in-process inspection ensures every operation, every dimension and every setup is verified, reducing variation and maintaining consistent accuracy across the full production run.

Quality Plans

For complex or highly regulated projects, we develop bespoke Quality Plans outlining inspection stages, control methods, documentation requirements and validation criteria. These plans ensure every component is manufactured under controlled, repeatable conditions.

Manufacturing You Can Trust

Our Top Services

CNC Milling

With our extensive range of 4 and 5 axis precision CNC milling centres we can deliver the highest quality of machined components to our customers specification.

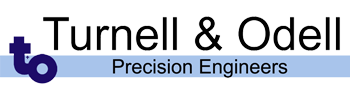

CNC Turning

We offer the highest quality precision CNC turning from bar fed lathes to larger chucking machines, many with driven tooling.

Welding

We offer MIG, TIG & STICK welding, along with Plasma and Gas cutting to complement our precision machining facility.

Grinding

Our precision surface and cylindrical grinding facilities enable fine surface finishes and tight dimensional tolerances for small to medium production batches.