Turnell & Odell

Rotational Moulding

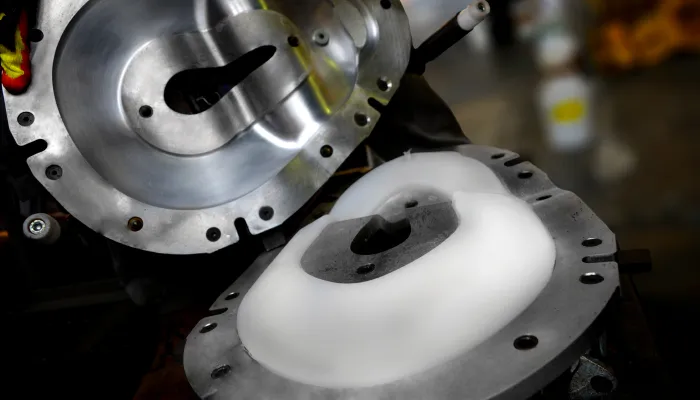

Turnell & Odell deliver high-quality precision-engineered components that support the performance, reliability and efficiency of rotational moulding equipment. With decades of CNC machining experience, multi-material capability and advanced finishing processes, we help manufacturers maintain durable, consistent and repeatable moulding operations across a wide range of plastic products. Our engineering expertise ensures machinery remains robust, accurate and production-ready.

Why Rotational Moulding Requires Precision Engineering

Rotational moulding machines operate under continuous heat, rotation and loading cycles. For this process to run smoothly, components must be engineered for accuracy, heat resistance and long-term durability. Turnell & Odell supply critical machined parts, assemblies and fixtures designed to maintain alignment, support uniform mould rotation and ensure stable moulding conditions — delivering dependable performance in every cycle.

Precision

UKs Best

Why the Defence Industry Chooses Us

Skills

Supporting Large, Durable & Heat-Exposed Components

Rotational moulding equipment often uses large, heavy-duty components that must endure intense thermal cycles and mechanical movement. Turnell & Odell manufacture robust, accurately machined parts such as arm assemblies, mould supports, bearings housings, pivot components and structural plates. Our engineering ensures stable rotation, reduced wear and consistent mould heating — contributing directly to product quality and operational reliability.

From Prototype Parts to Full Production Support

Whether developing a new moulding system or upgrading existing machinery, Turnell & Odell offer full lifecycle support. From initial prototype components through to ongoing production and replacement parts, our flexible machining capability allows rotational moulders to maintain uptime, trial improvements and respond quickly to changing production needs.

Quality, Accuracy & Longevity for Moulding Machinery

Rotational moulders rely on equipment that performs without interruption. Turnell & Odell operate under ISO-aligned quality systems with advanced inspection methods to deliver components that meet demanding machine requirements. Our precision engineering enhances equipment stability, extends component life and reduces maintenance — giving manufacturers confidence in every production run.

Partner With Turnell & Odell for Rotational Moulding Engineering

Choosing Turnell & Odell means working with a precision engineering partner who understands the unique challenges of rotational moulding. We deliver durable, accurately engineered components that support machine reliability, improve moulding consistency and enhance production efficiency — helping you deliver exceptional moulded products with confidence.

Turnell & Odell

Contact Us Now

Address

Sanders Road

Finedon Road Ind. Estate

Wellingborough

Northants

NN8 4NL

Book By Phone

+44 (0) 1933 222061