Services

Metal Treatment & Finishing

High-performance treatments and finishes that enhance durability, appearance, and long-term reliability across precision-engineered components

Using specialised treatment processes and expert finishing techniques, Turnell & Odell improve material performance, protect surfaces, and ensure each part meets demanding industry requirements. Our capabilities support both prototype and production work, delivering consistent results across a wide range of metals and alloys.

Turnell & Odell

Specialist metal treatment and surface finishing

Surface Preparation & Protection: These processes enhance wear resistance, corrosion resistance, and overall surface performance.

Heat Treatment & Hardening: Ideal for components requiring increased strength, stability, and wear resistance, our heat treatment processes deliver controlled results that improve long-term performance. Techniques such as hardening, tempering, and stress relief ensure components remain reliable in demanding environments.

Every treated part undergoes careful monitoring and inspection to ensure consistent metallurgical properties. With advanced equipment and strict process controls, we achieve reliable and repeatable results across all material types.

Surface Coating & Finishing: Suitable for both functional and aesthetic applications, our finishing processes improve surface quality, corrosion resistance, and overall component longevity. This includes polishing, deburring, coating preparation, and fine finishing of multiple materials.

These methods ensure components meet exact specifications and required surface conditions, supporting industries such as automotive, aerospace, energy, and precision manufacturing — where long-lasting performance and finish quality are essential.

Precision Engineering Services

Get In Touch With Us

Call us anytime

+44 (0) 1933 222061

Email us

sales@toengineering.co.uk

Get A Quote

Improve both performance and durability

Skills

Enhanced Strength, Protection & Surface Quality

Our treatments are engineered to improve both performance and durability. Heat treatment increases hardness and resilience, while finishing techniques create smooth, uniform surfaces that enhance wear resistance and reduce friction. These processes ensure your components maintain stability, accuracy and strength under demanding operational conditions.

Flexible Treatment Solutions for Prototypes & Production

Whether you require single treated components, small-batch processing or full production volumes, Turnell & Odell provide flexible solutions tailored to your needs. We support manufacturers, machinery builders and specialist industries with reliable treatment and finishing services that integrate seamlessly into existing production workflows and quality systems.

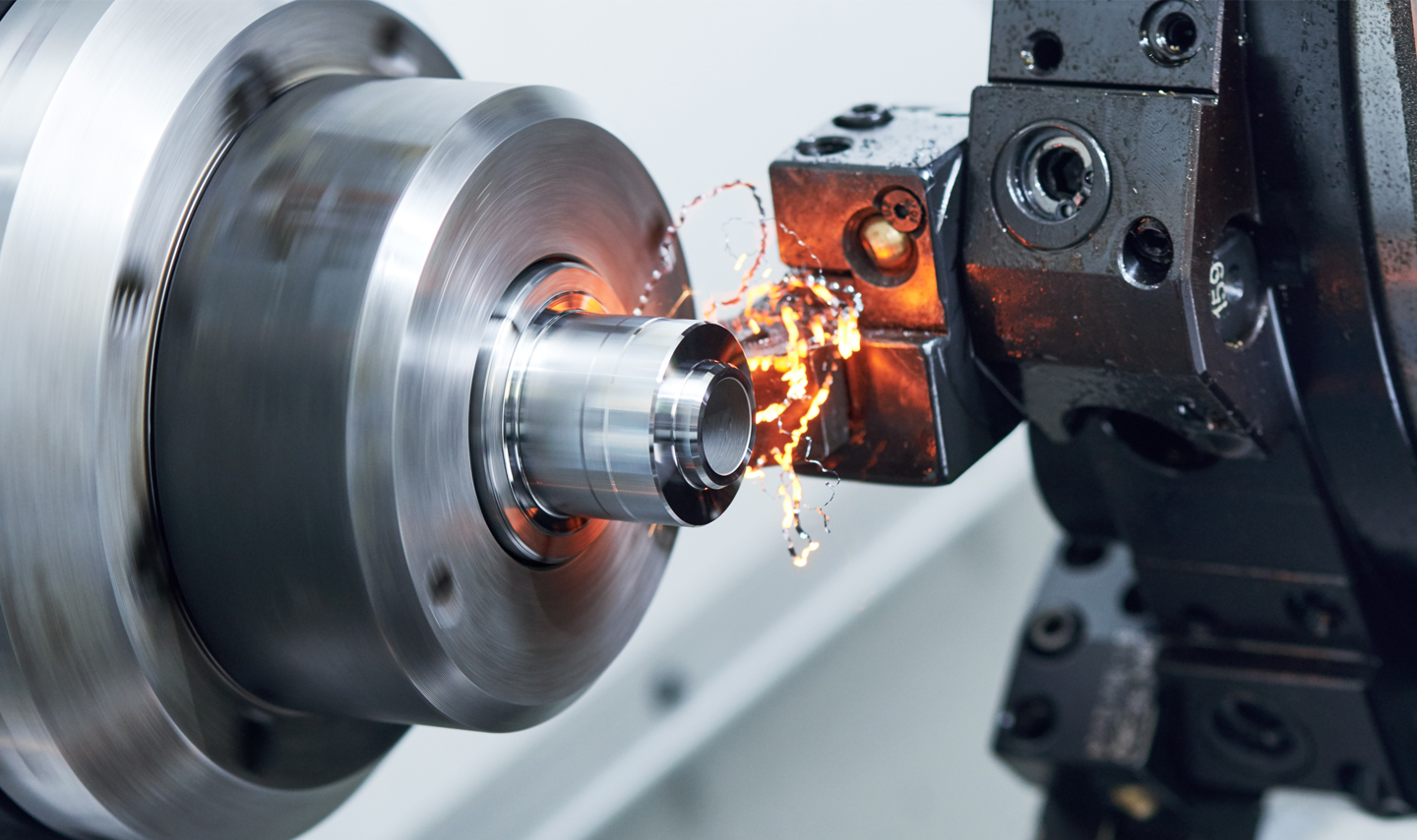

Quality-Controlled Processes for Reliable Performance

Every treated component undergoes strict quality control, including inspection and verification to ensure the treatment meets precise specification. Turnell & Odell follow ISO-aligned processes and maintain full traceability throughout treatment and finishing. This ensures consistency, repeatability and compliance with industry requirements, giving customers confidence in long-term performance.

Partner With Turnell & Odell for Precision Metal Treatment & Finishing

Choosing Turnell & Odell means partnering with experts who understand how vital surface quality, durability and material performance are to your engineering project. Our metal treatment and finishing services add long-term value, reduce maintenance needs and support the overall reliability of your machinery, equipment or components.

Manufacturing You Can Trust

Our Top Services

CNC Milling

With our extensive range of 4 and 5 axis precision CNC milling centres we can deliver the highest quality of machined components to our customers specification.

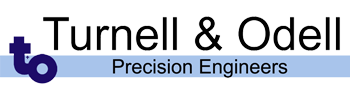

CNC Turning

We offer the highest quality precision CNC turning from bar fed lathes to larger chucking machines, many with driven tooling.

Welding

We offer MIG, TIG & STICK welding, along with Plasma and Gas cutting to complement our precision machining facility.

Grinding

Our precision surface and cylindrical grinding facilities enable fine surface finishes and tight dimensional tolerances for small to medium production batches.